Was originally invented to describe logic made from relays. Language very popular for programming Programmable Logic Controllers (PLCs). Ladder logic is a method of drawing electrical logic schematics. Has been expanded to include functions such as Counters, Timers, shift Registers and Ladder Logic is a graphical programming language, initially programmed with simpleĬontacts that simulates the opening and closing of relays. Standards to which they abide their planned evolution as well asthepotentialbenefitsof Some attention is also paid to the industrial

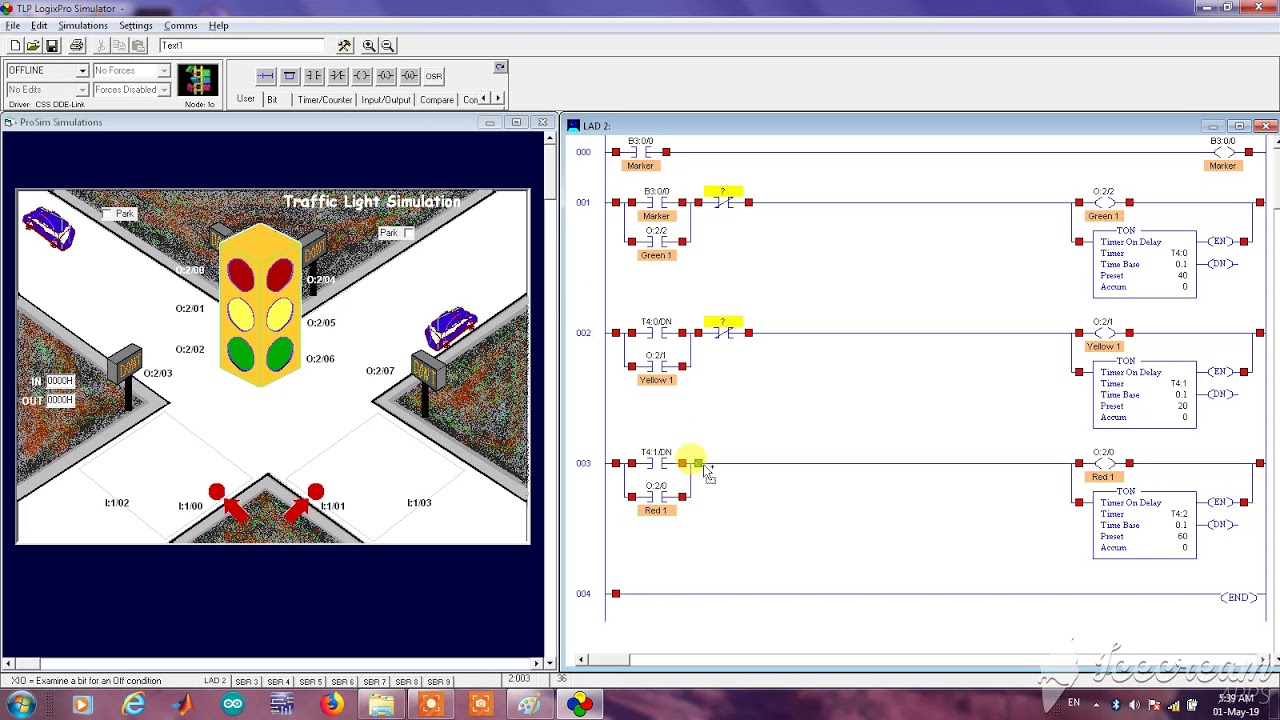

Their interface to the process hardware, the functionality and the applicationĭevelopment facilities they provide. This paper describes the PLCs systems in terms of their architecture, The way for me to complete this project report.Įlectronics and Communication EngineeringĪn industrial PLCs system is used for the development of the controls of I would also mention the outstanding support given by my parents who paved I also thank the staff of Amity School of EngineeringĪnd Technology who took out their precious time and made various arrangements Abhaynath Malviya, Senior IndustrialĮlectronics Engineer, Insulator and Electrical Pvt. Therefore, it is my sole responsibility to acknowledge them. This report is an outcome of the contributions made by some of the peoples. (Training Division of Insulators and Electricals Ltd.) Summer Internship Report For PLC Programming of Traffic light through Ladder Logic The name is based on the observation that programs in this language resemble ladders, with two vertical "rails" and a series of horizontal "rungs" between them. It was originally invented to describe logic made from relays. It is now a graphical language very popular for programming Programmable Logic Controllers (PLCs).

Ladder Logic programming has been expanded to include functions such as Counters, Timers, shift Registers and math operations. Ladder Logic is a graphical programming language, initially programmed with simple contacts that simulates the opening and closing of relays. Some attention is also paid to the industrial standards to which they abide their planned evolution as well as the potential benefits of their use. This paper describes the PLCs systems in terms of their architecture, their interface to the process hardware, the functionality and the application development facilities they provide. For free download Subscribe to and Follow then please contact +91-9045839849 over WhatsApp.Īn industrial PLCs system is used for the development of the controls of machinery.

0 kommentar(er)

0 kommentar(er)